King Epoxy Emblem Co., Ltd »

Plastic Injection Molding

The most commonly used process for manufacturing plastic parts.

KTP Plastic Injection Molding Capabilities

King Epoxy Emblem Co., Ltd efficiently meets high-volume demands using plastic injection molding. Our engineered molds ensure precision and quality, meeting strict standards. Our molds produce large quantities of parts at a lower cost without compromising quality. Injection molding minimizes waste and scrap rates, resulting in cost savings for our customers.

Custom Plastic Injection Molding

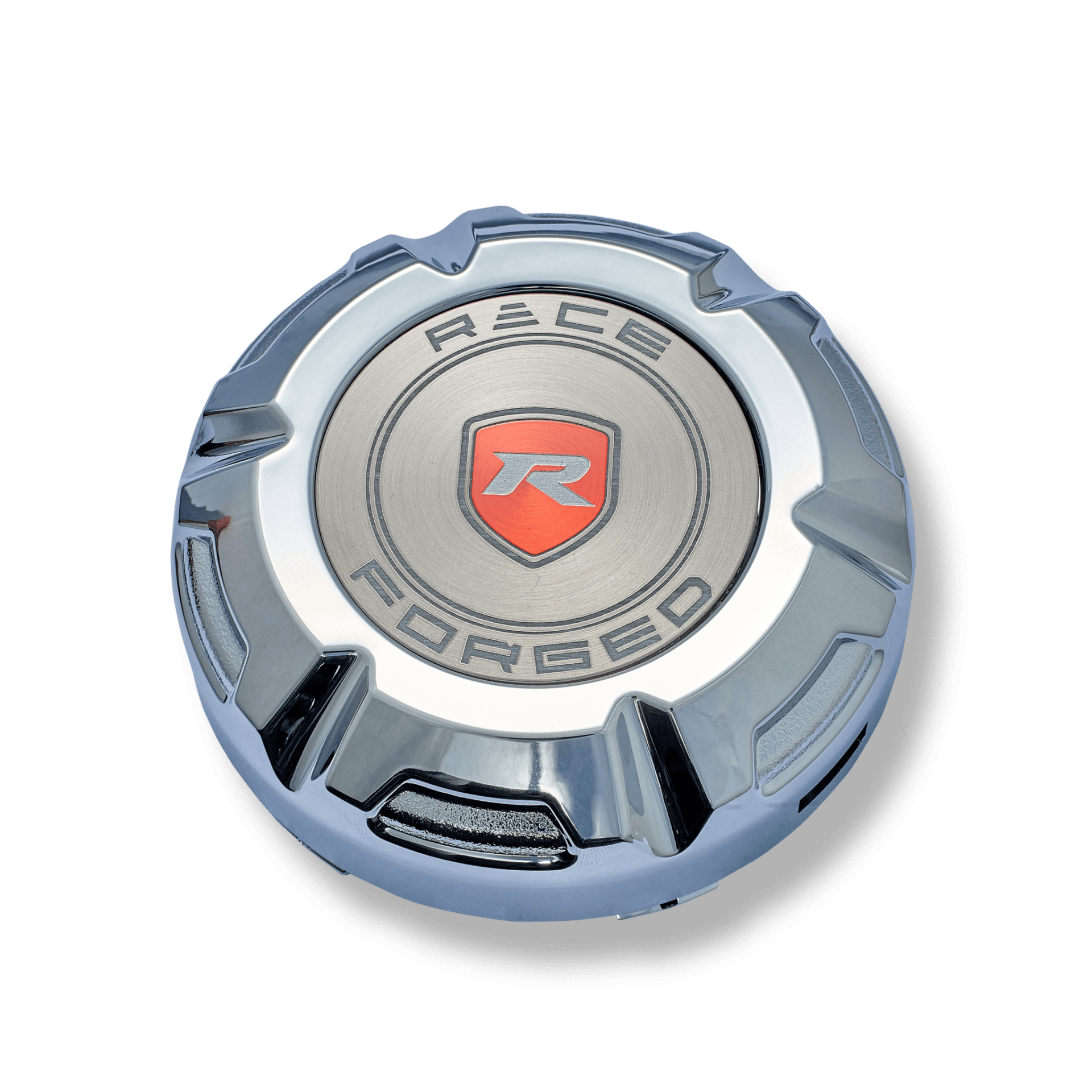

King Epoxy Emblem Co., Ltd’s skilled engineers design molds to customer specifications, ensuring every component meets our rigorous quality standards. Our plastic injection molded parts are renowned for their high tolerance and flexibility, allowing for complex designs with ease. From concept to reality, we bring our customers’ ideas to life. After thorough quality checks, parts proceed to our value-added finishing services, including spray painting, laser etching, and more.

As a trusted name in interface manufacturing, we seamlessly integrate any graphic design into our plastic injection molding process, leveraging our reputation for quality. Contact our engineers today to discuss your needs and create molds that exceed your expectations.

Spray painted.

Pad printed.

Ink filled.

Chrome plated/vacuum metalized (bronze, nickel, dark chrome colors).

Brushed hairline surface.

Double shot.

Threaded inserts.

Laser etched after painting.

Light pipe and light guide (PC or Acrylic).

Heat-staked or welded.